Three dimensional printing is an additional substance manufacturing measure which incorporates the making of significant articles from a data progressed archive. Added substance manufacturing system is the making of solid things by including reformist layers of the material until the article is conveyed. All of the extra layers are regularly sheets of the material which takes the shape needed by the organizer. 3D printing ordinarily starts with the making of a virtual construction by and large got done with the help of a Computer Aided Design CAD. Experts in arranging objects with CAD can do the hidden construction on their PC prior to moving the print archive to the 3D printer. For the people who need to print a current thing, a 3D scanner can be used to make a high level copy of the article prior to setting it into the 3D showing program.

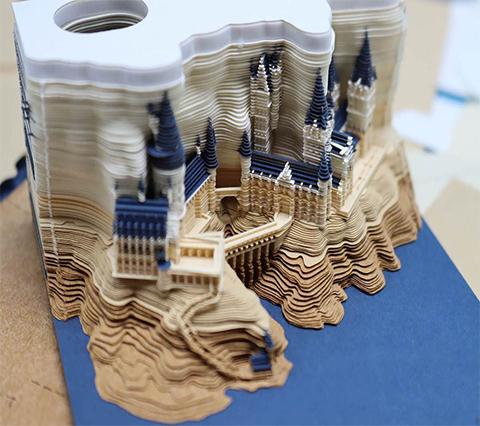

3D printers use different sorts of developments to comprehend their articles and a part of these headways are inspected underneath. The 3d printing development uses an extraordinary laser to merge little particles of the ideal materials together and see about Omoshiroi Block 3D Memo Pads. Some noticeably used materials are plastic, imaginative, glass and metals. These materials are ordinarily dealt with to the printer in powdered construction after which it wires them by looking at the layers made by the 3D showed program. After the layer is checked, the powder bed adds one layer of thickness to the thing being conveyed in order to move beyond anyone’s expectations in the creation. This cycle is reiterated times and times until the whole thing is done. One great situation of the SLS technique is that bounty powders in the making of an article can be reused and used for another creation.

This methodology resembles the photo polymerization strategy where solids are conveyed from liquids. The 3D memo pad advancement incorporates the use of a tank of liquid splendid reparable photopolymer sap and a brilliant laser to manufacture reformist layers of the article. In order to make a layer, the laser bar picks a cross-space of the design outwardly of the liquid sap and opens it to splendid light thusly reestablishing and solidifying it, prior to adding it to the past layer. This advancement incorporates the use of a metal wire or plastic fiber generally speaking slackened up from a circle and used to deftly the essential material to a removal ramble prepared for executing the stream on or. The ejection ramble is warmed to mollify the information material and it can move either equally or vertically dependent upon the direction it gets from a Computer-Aided ManufacturingCAMprogramming pack.

)

Welcome to our blog!